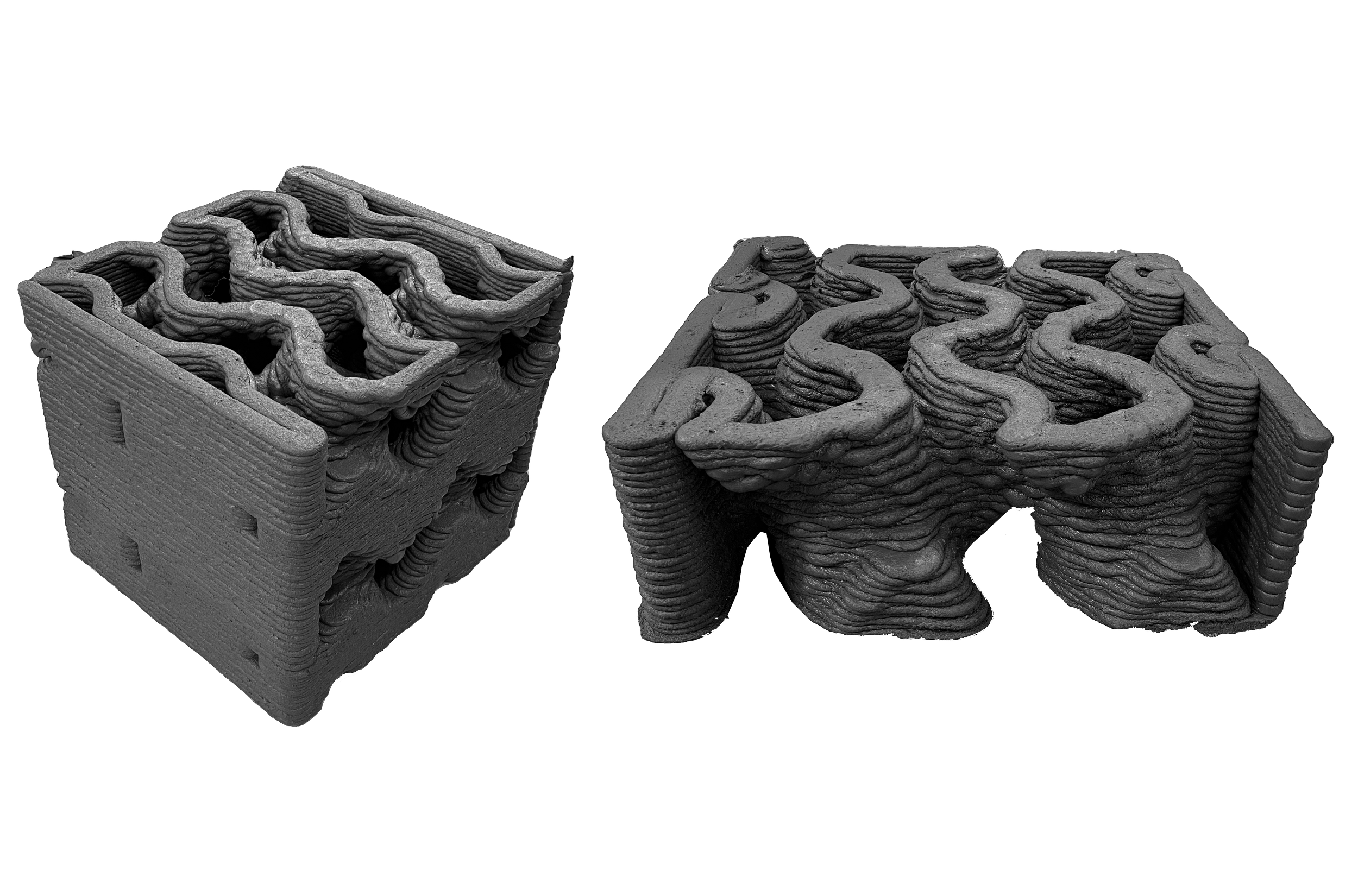

The gyroid is a triply-periodic minimal surface that can efficiently distribute large amounts of compression stress. Naturally occurring in the scales of butterfly wings, this shape is difficult to produce due to its naturally occurring steep sinusoidal cantilevers.

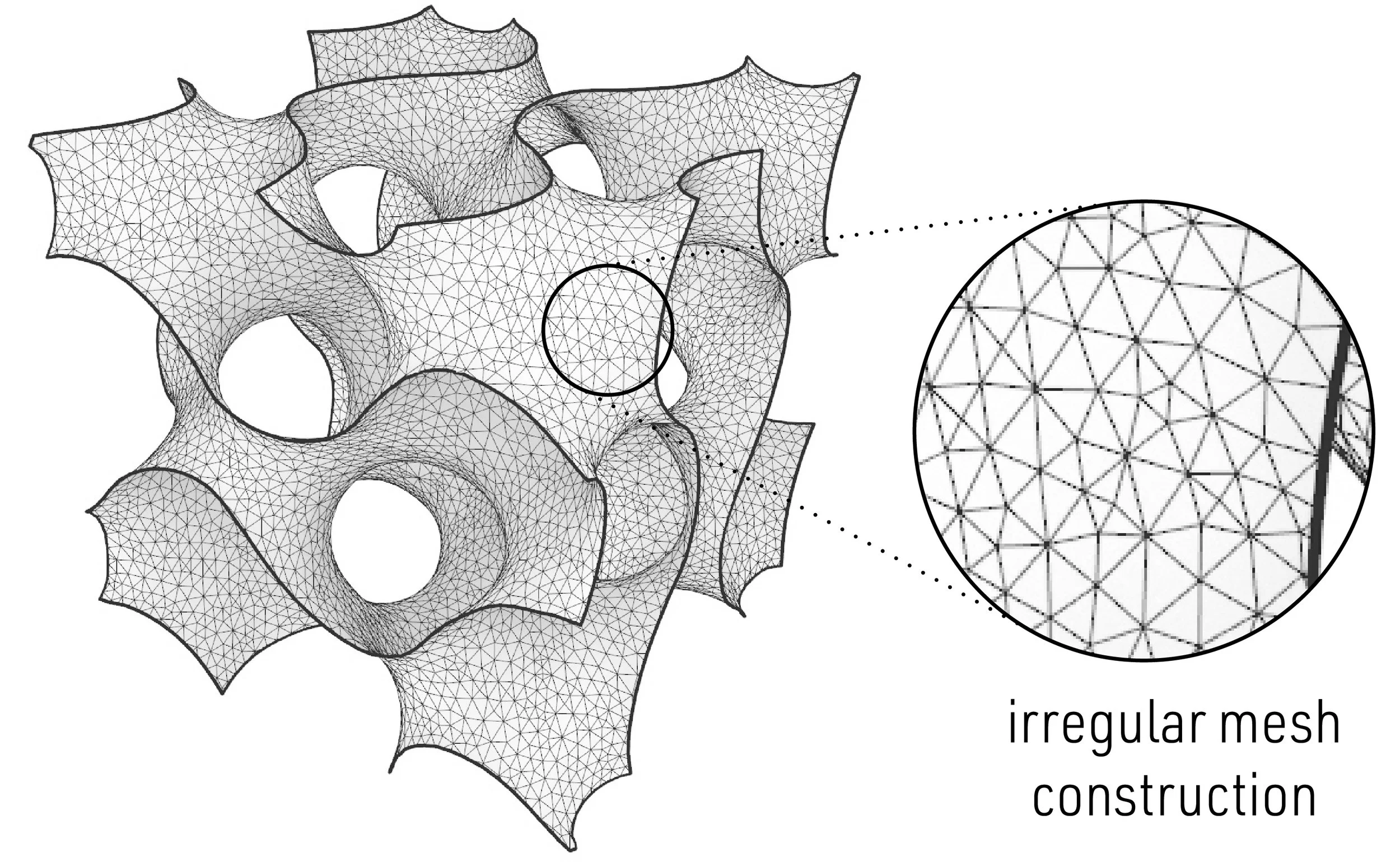

Our first iterations utilized Grasshopper to create the gyroid from complex mesh polygons.

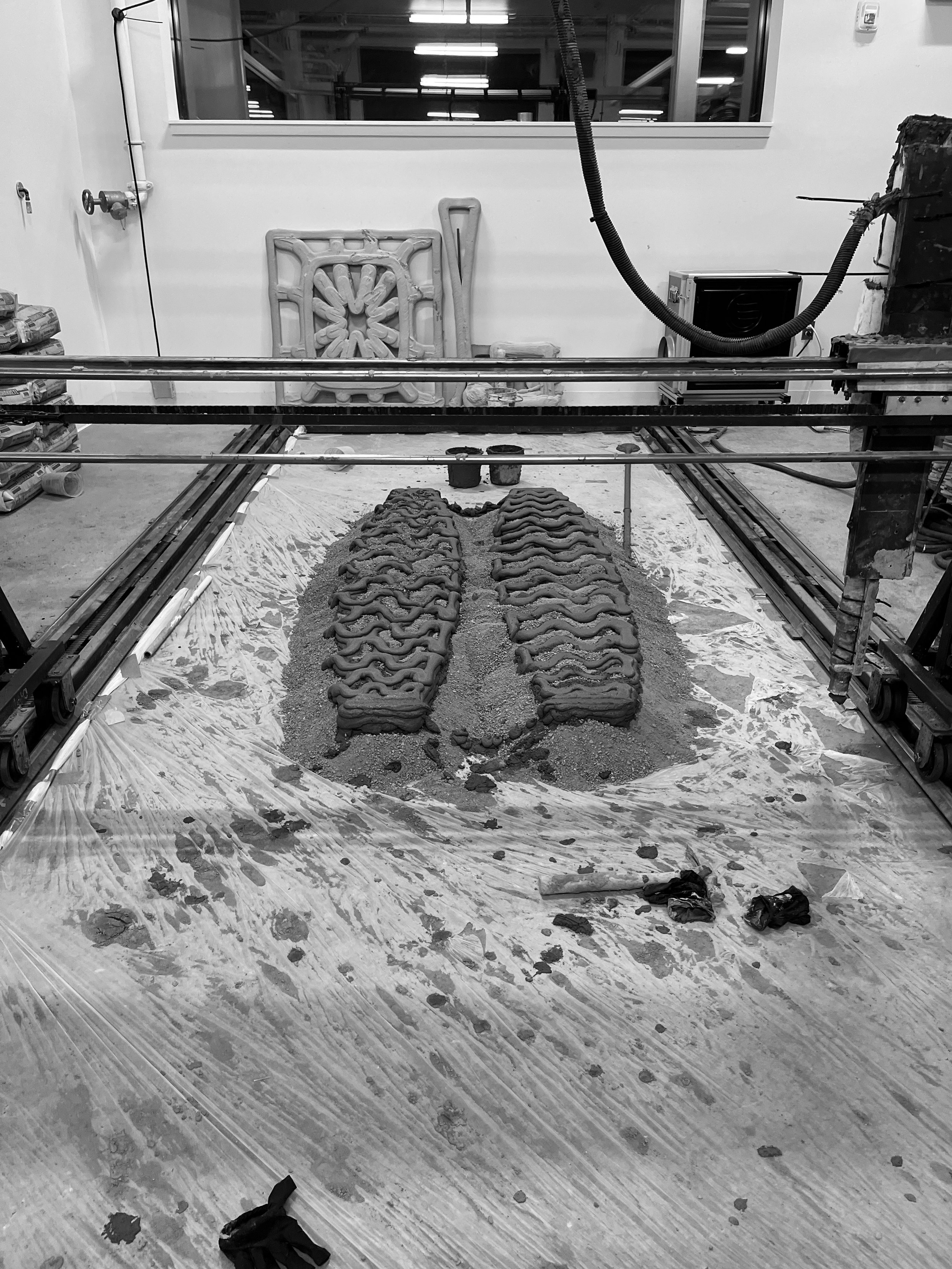

In our initial gyroid 3d printed studies utilizing a gantry 3d printer, it became clear that a method of gyroid creation was needed in order to efficiently compute the shape with curves and surfaces. Our first iterations utilized Grasshopper to create the gyroid from complex mesh surfaces.

Following the creation of a surface and curved based method of construction, paper and computer iterations focused on generating closed toolpaths for gyroid printing.

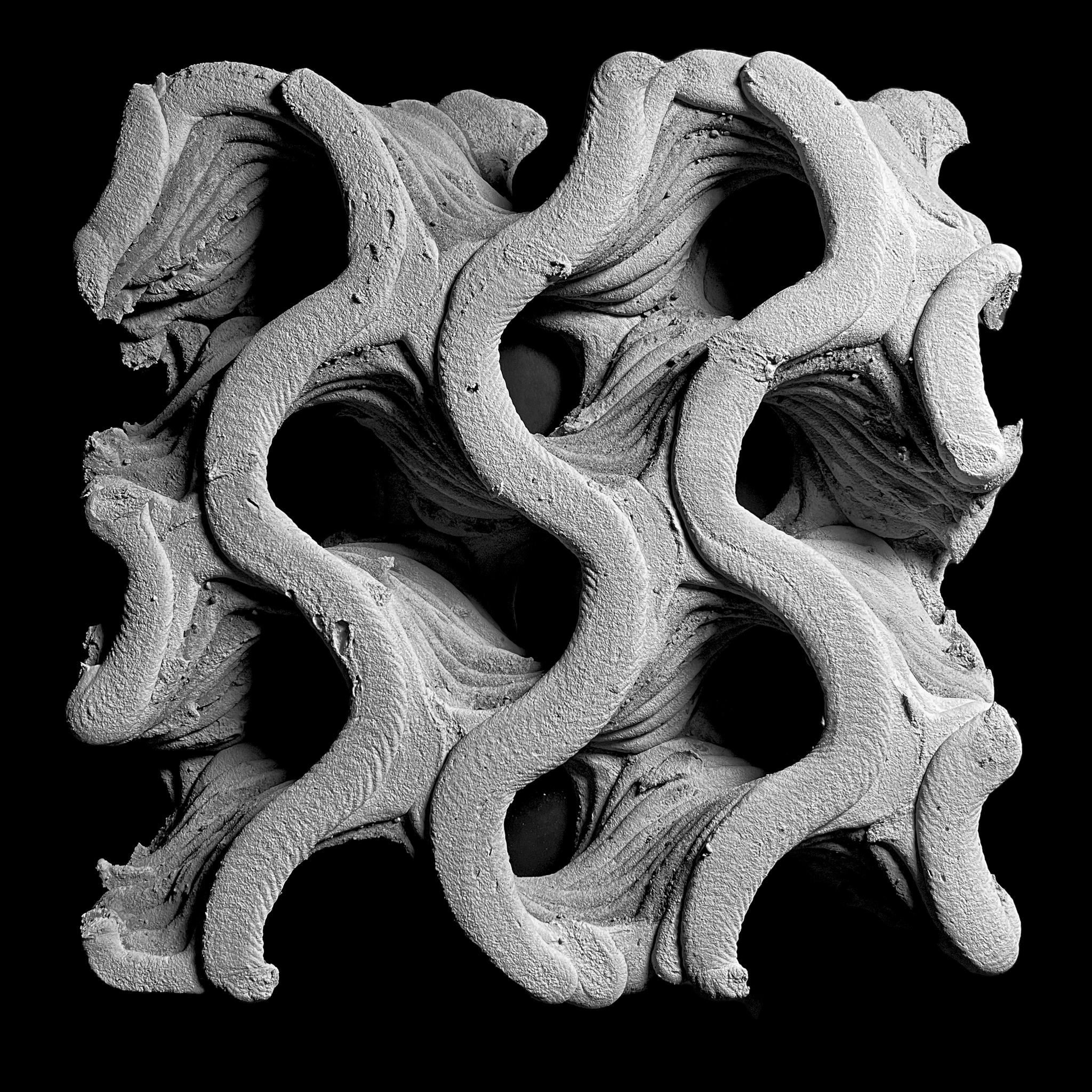

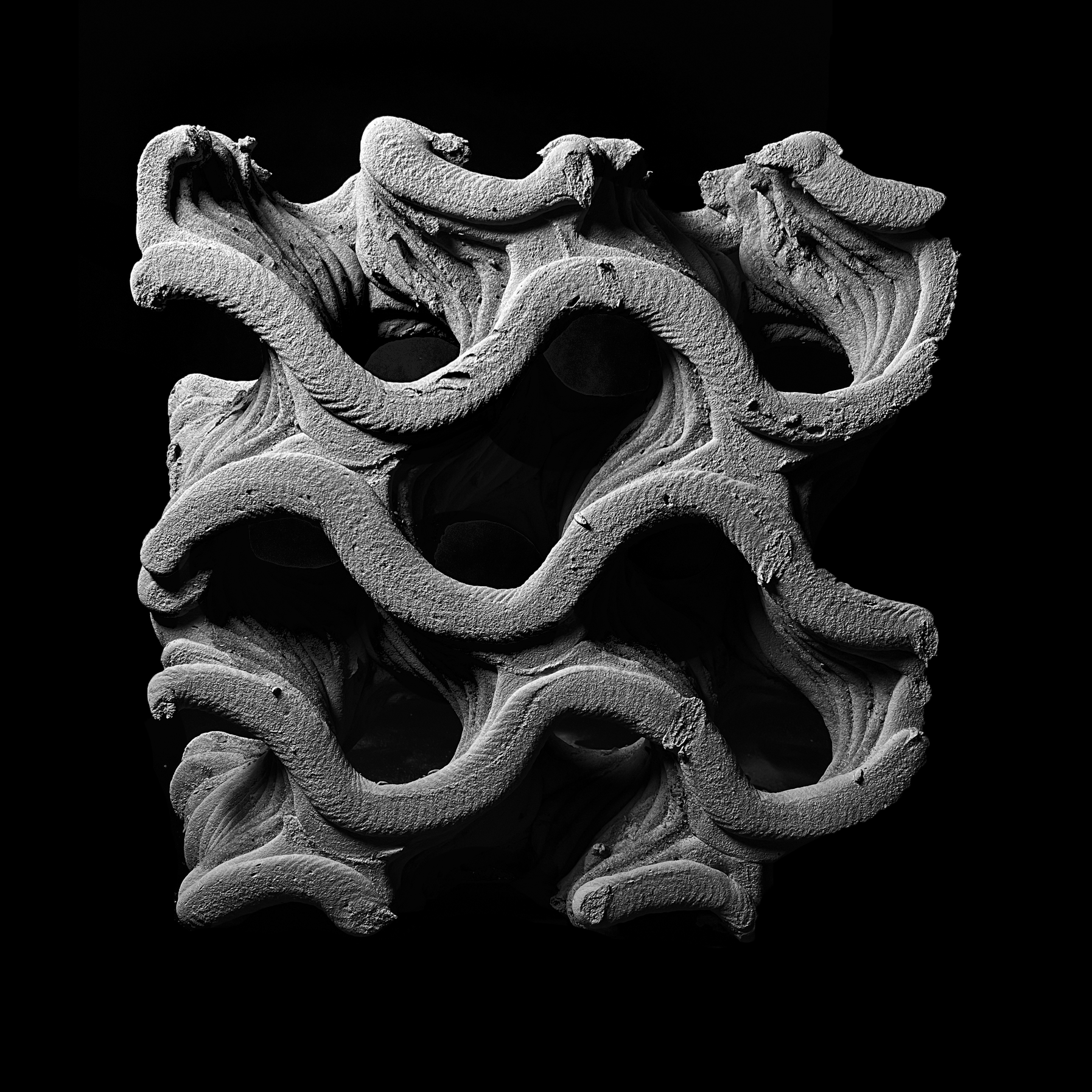

Gyroid density tests were first computed computationally, revealing limitations on module size in relation to concrete bead width.

In collaboration with Cornell’s Engineering Department, 6-axis robotic arms helped to further refine our density limitations and gyroid potential.

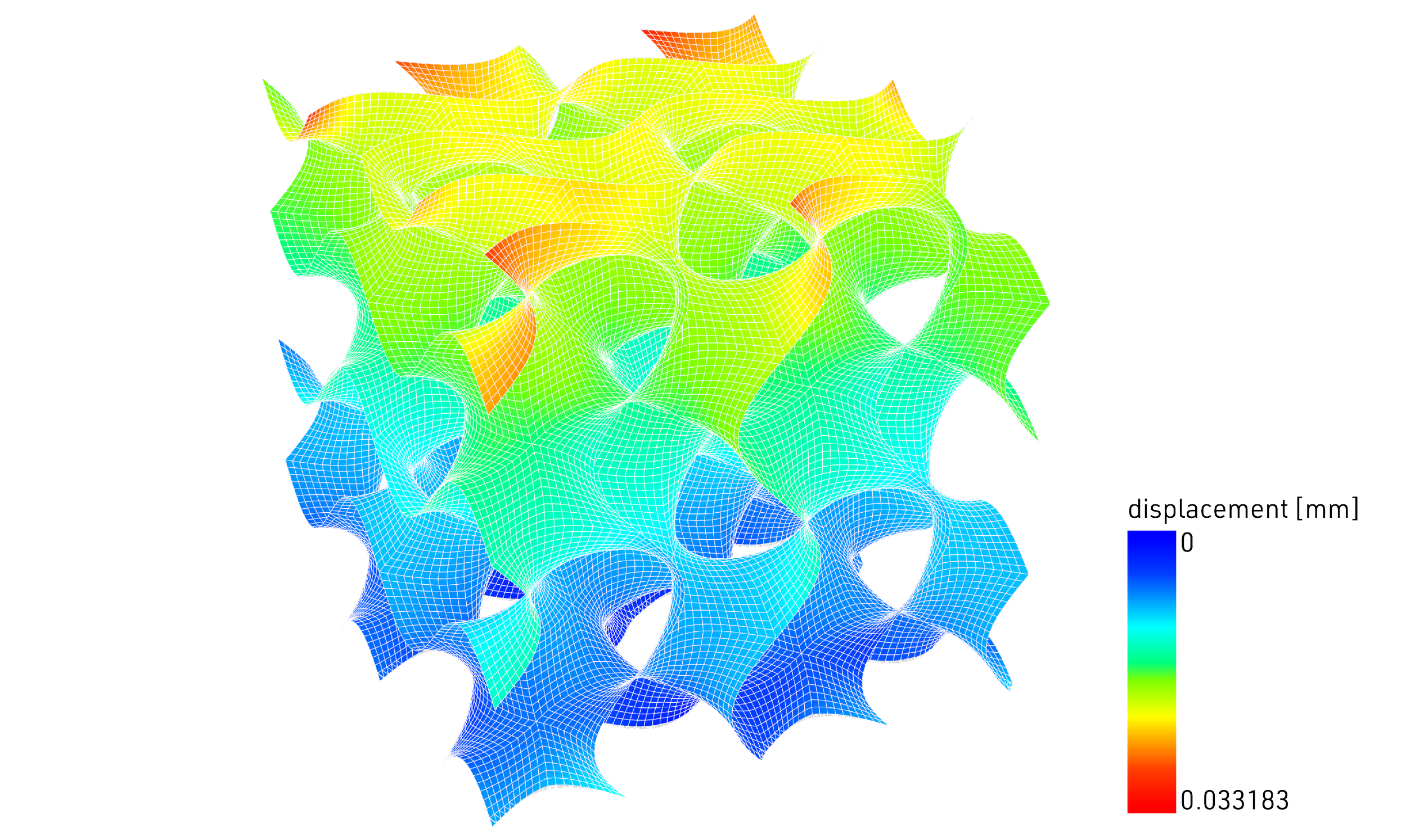

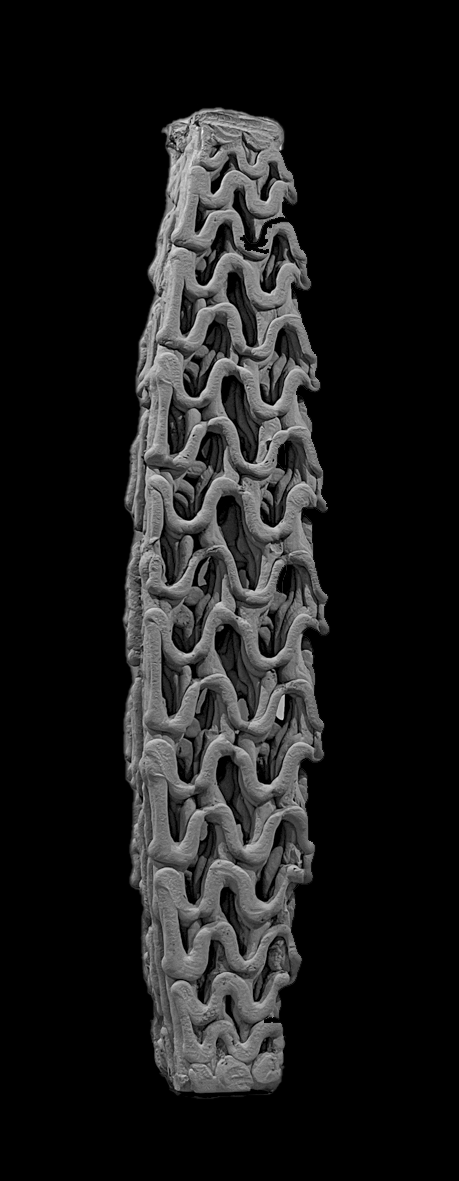

In translating our studies into an architectural prototype, this column was first optimized through a generative evolutionary design solver (Galapagos,) then analyzed using FEA analysis (Karamba.)

Printing utilized 3 people, an operator for the gantry 3d printer, a supervisor of concrete flow rate, and a layer of sand to support cantilevers. Elsewhere, the next batch of concrete is prepared

Date

Spring 2023

Location

Ithaca, NY

Paper

Concrete Printed Gyroid Column

Team

John Conrad, Lawson Spencer, Roberto Amador, Tyler Linnehan, Moneev Genedy, Sriramya Nair, Sasa Zivkovic