Gothic architecture was a style which was prevalent from the 12-16th century, and grew as both an aesthetic and structural system through its primary use of stone

Seen above, the vaulting of Amiens Cathedral depicts a spatial condition which coincides with the dilemmas of primarily stone construction.

Amiens Cathedral shows us a structure which is primarily composed of the stacked and serial array of compression vault structures.

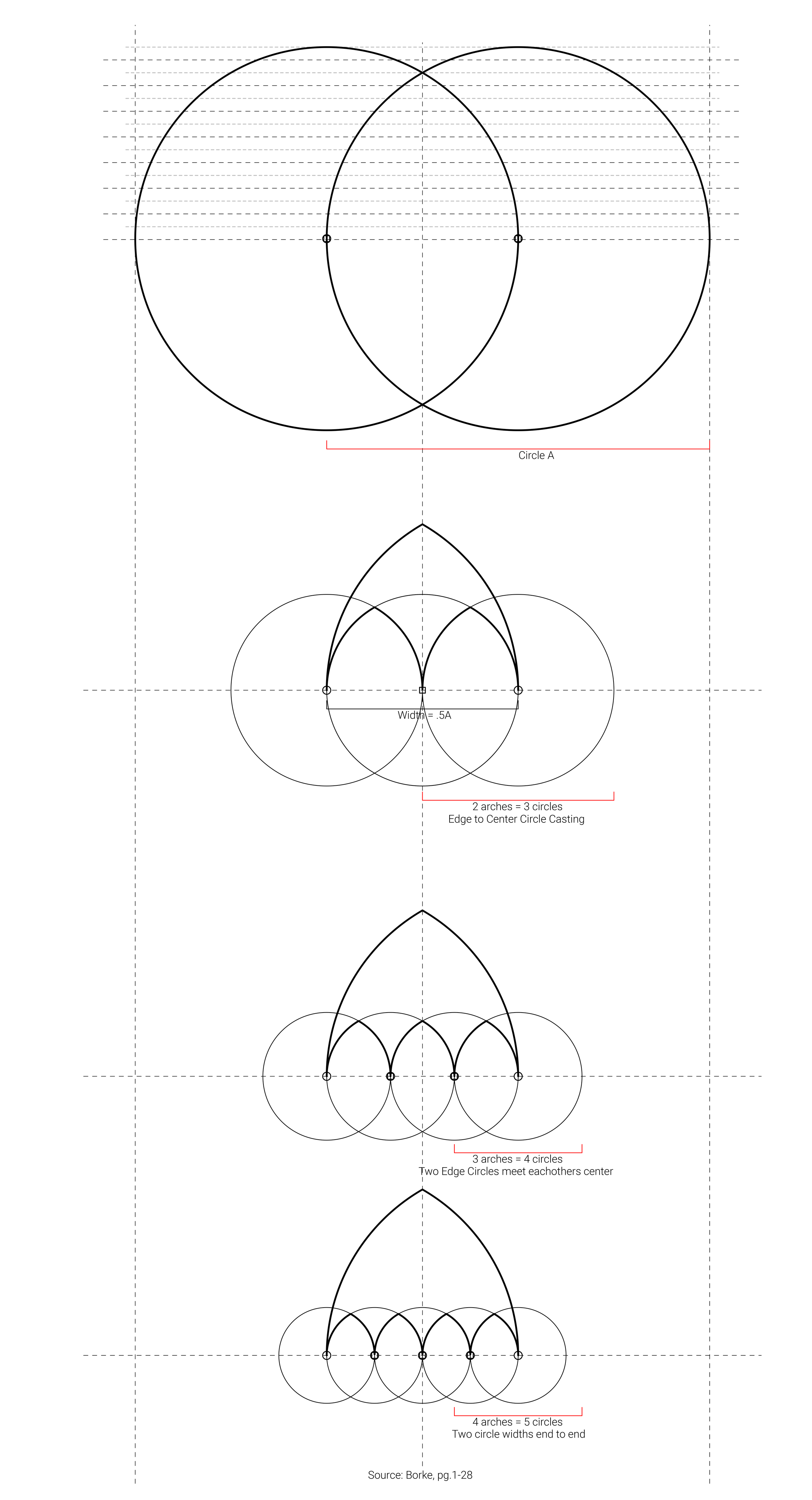

Through the gothic limitations, what is today achieved through more complex means of beam sizing, finite element analysis, and statics, was once achieved through the investigation of geometric proportions.

The linear rib was the ultimate display of the gothic's computational power. Ribs were both ornamental and diagrammatic, revealing the flow of compression as both ornament and structure. This language of gothic ribs was inspired by earlier Norse weaving techniques.

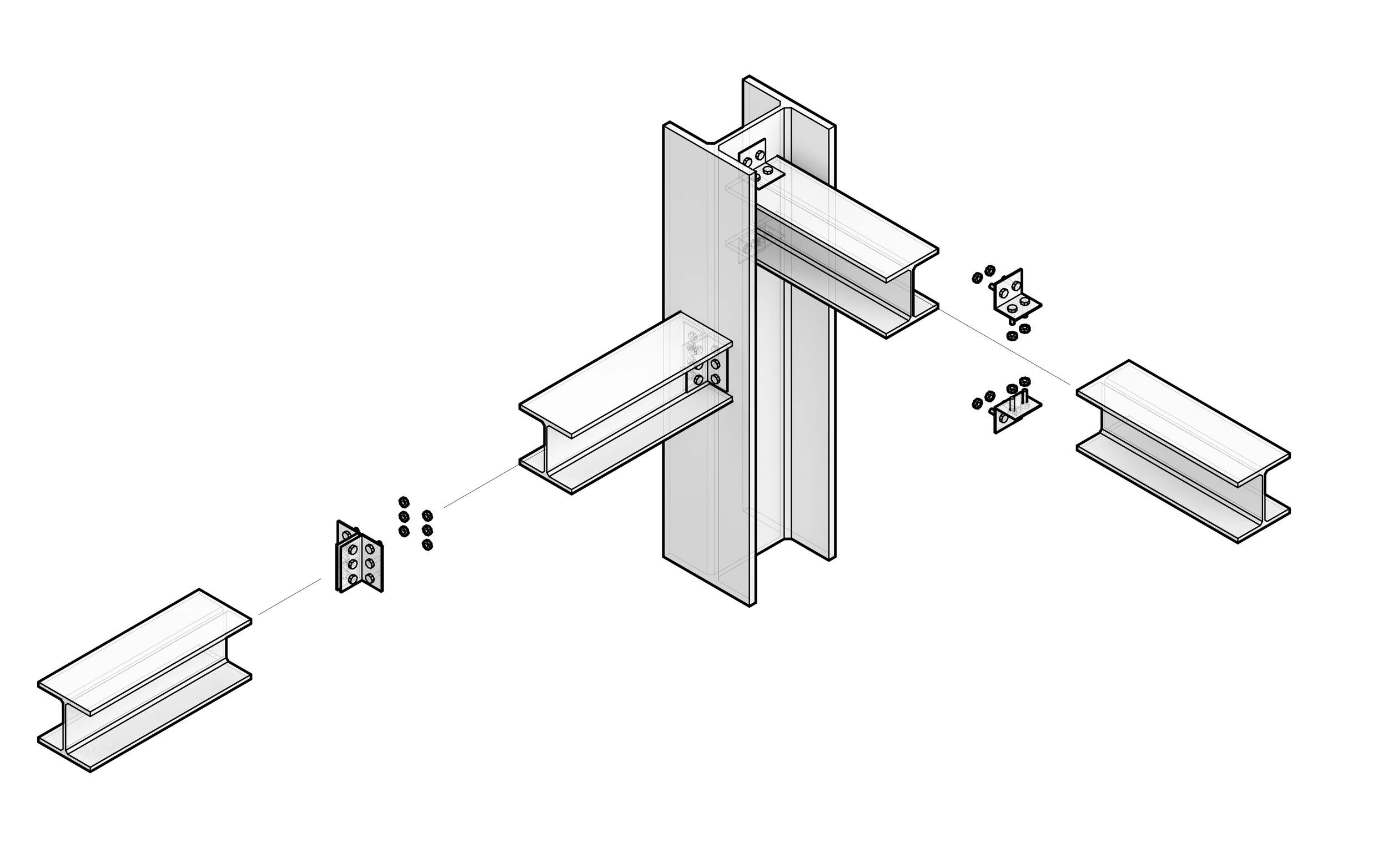

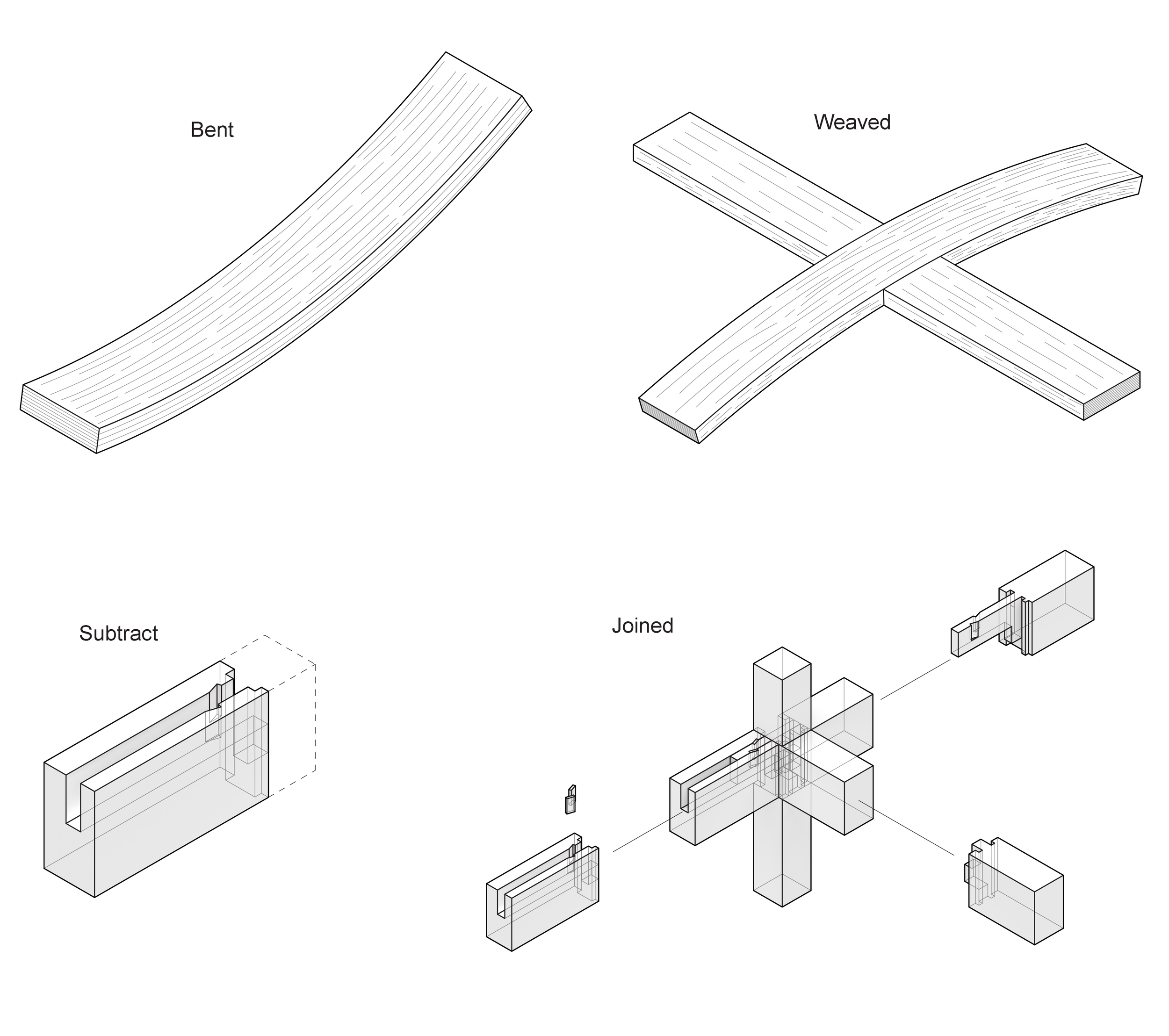

Above is a steel connection. Just as stone inhabited the weaving techniques from wood, the logic of steel has inhabited mass timber.

Mass timber is a relatively new material system. The current use of mass timber appears to have adopted the intelligence of older systems, and forgotten its past as wood.

How can this newer material of mass timber, trapped in the industrial logic of steel and concrete, be used in a manner more in accordance with its potential from wood?

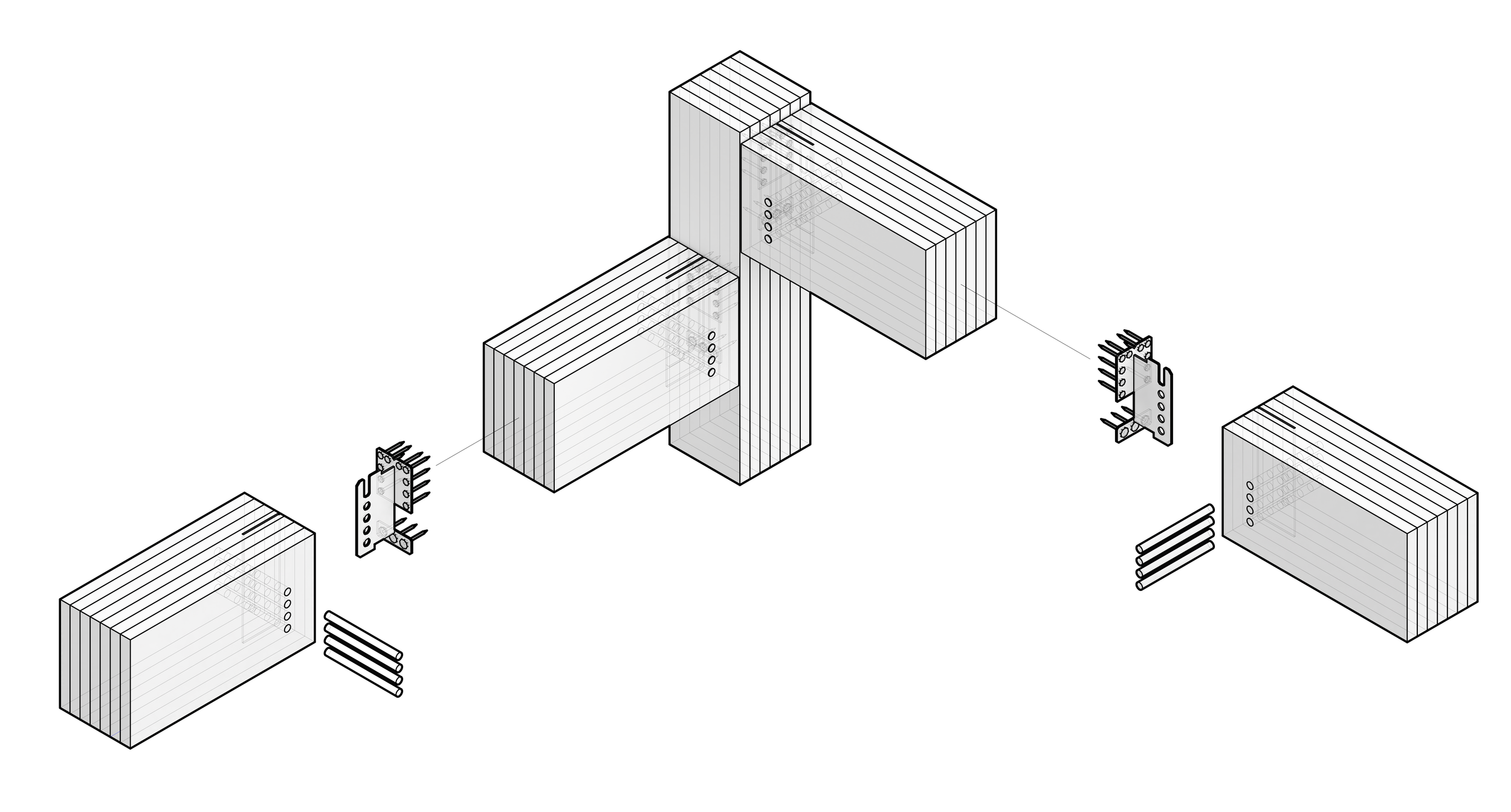

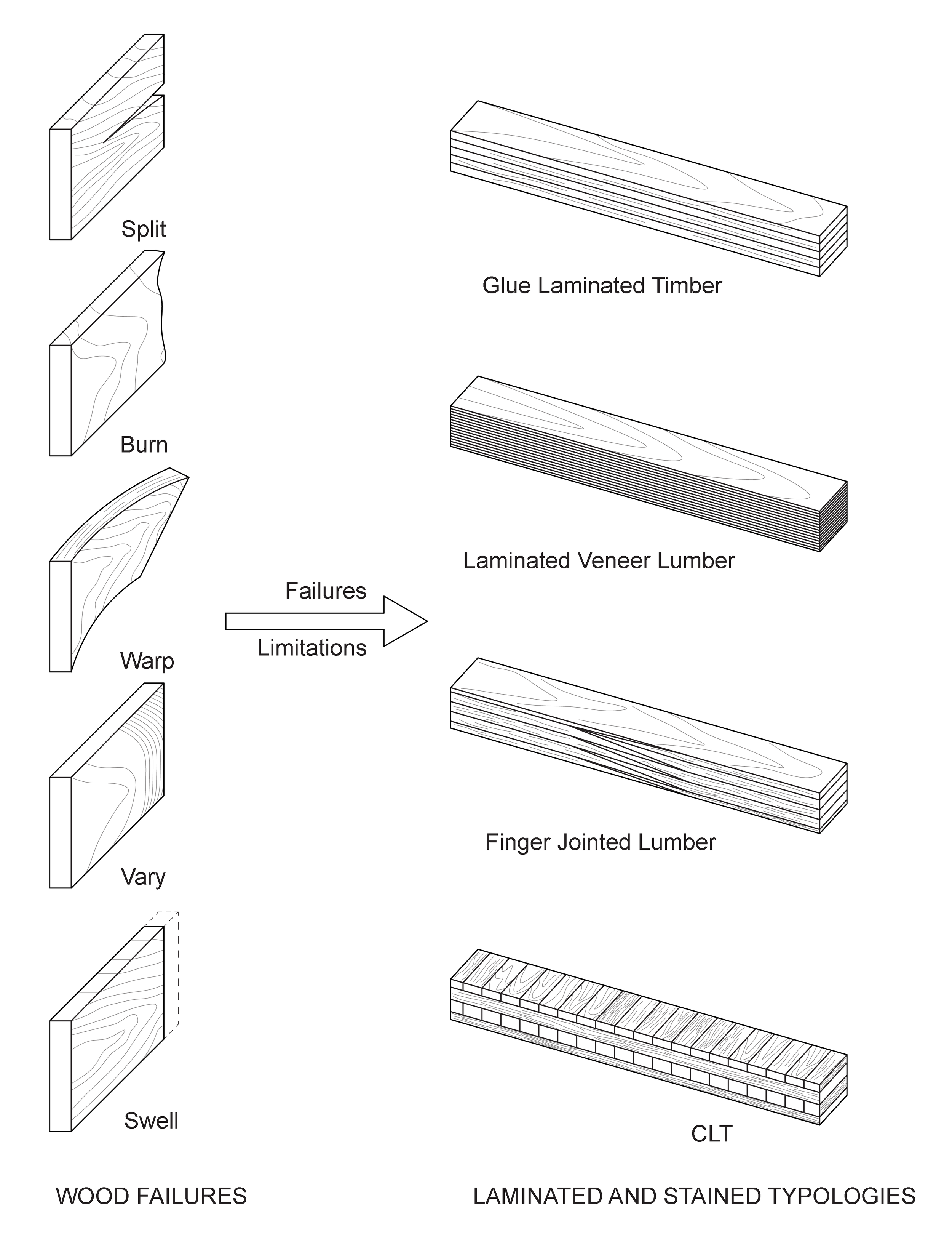

In order to test these claims, first we must observe what mass timber is as a material. It comes in several forms such as Cross Laminated, Finger Jointed, Laminated Veneer, and Glue laminated.

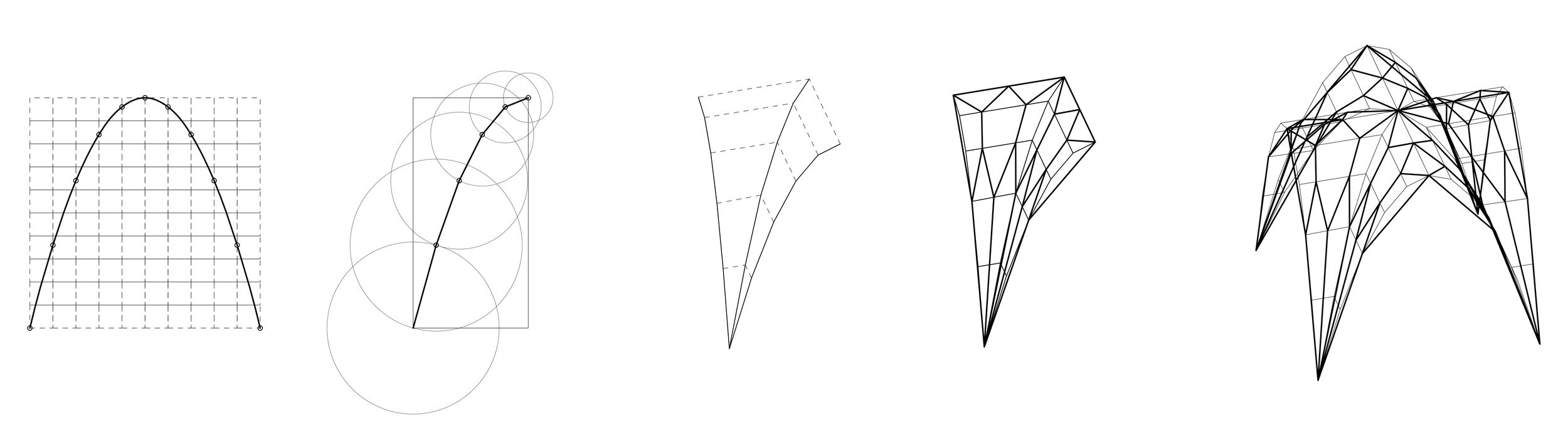

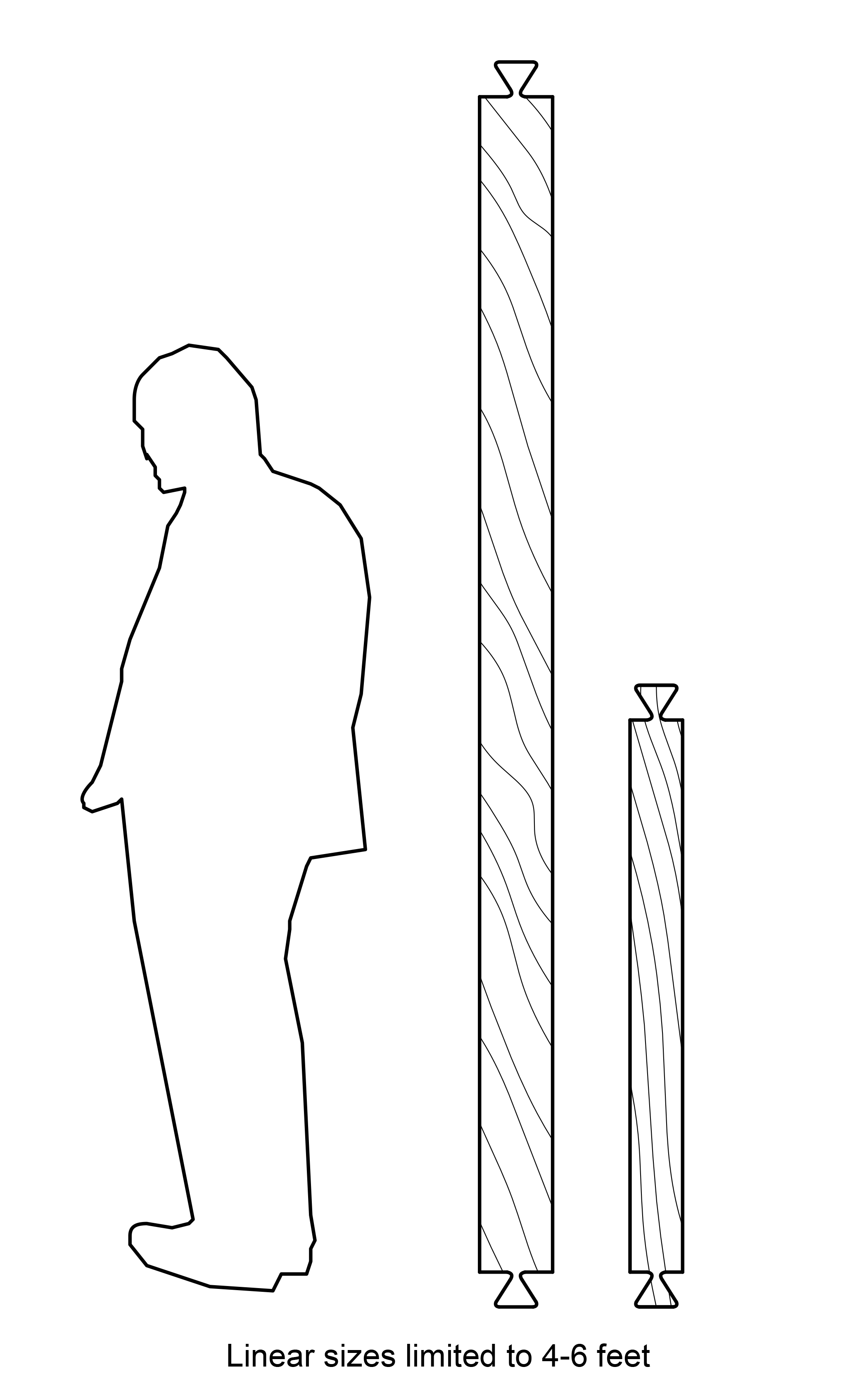

A funicular compression logic was determined. This funicular, linear logic would allow the timber to behave along its grain line, necessitating the use of glue laminated timber.

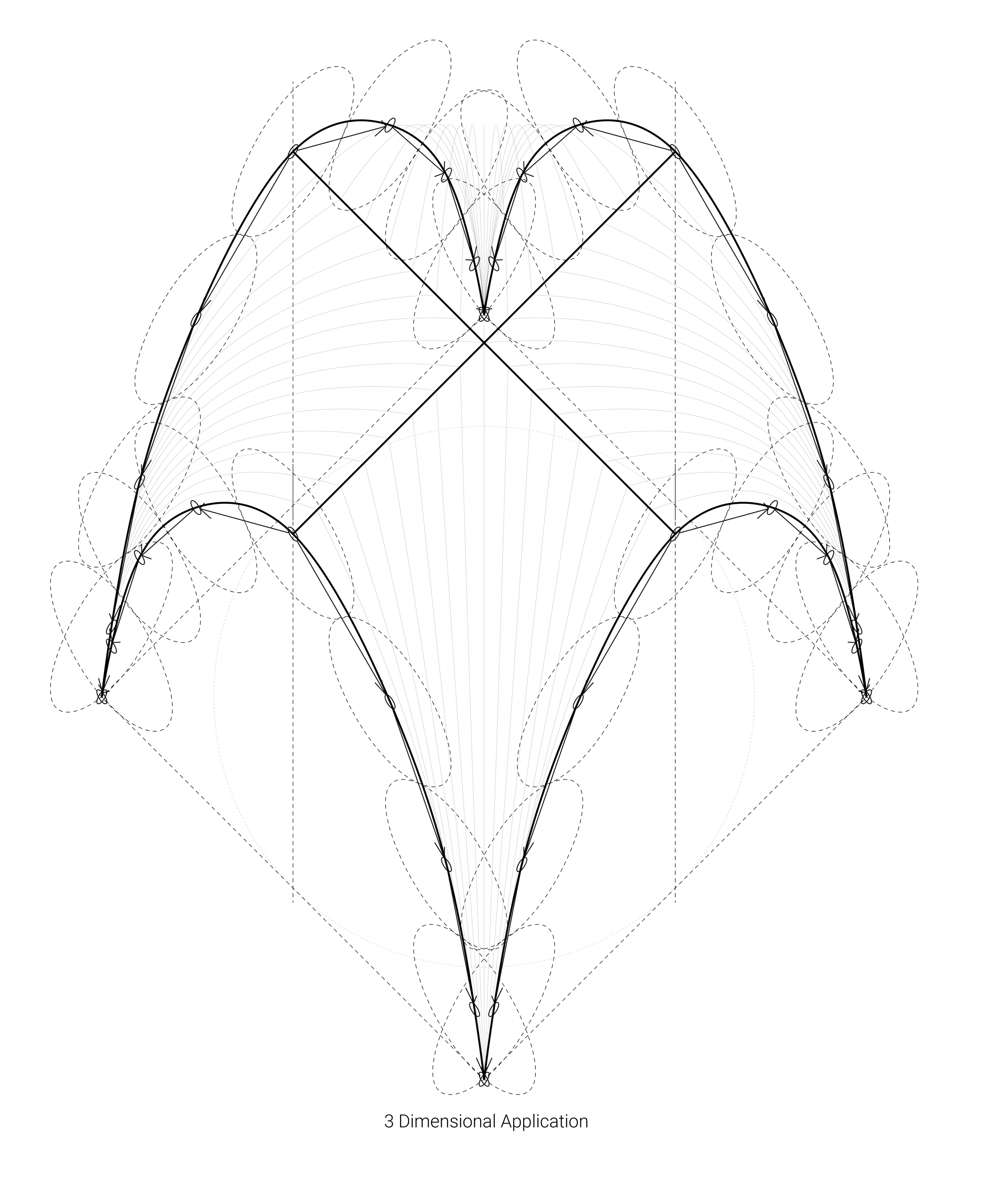

Above, a catenary curve is split in half, divided into five sections, and rotated 90 degrees around a base point. This method allows the conversion of funicular 2d geometry into a quarter-vault. Subdivision, as well as curve shape can be adjusted as needed.

Wood is good in both tension and compression, allowing it to operate in a funicular, compression based manner, while being able to accept any tension incurred

In place of wasteful scaffolding, pieces are entirely assembled from the bottom up, allowing one to use the previously assembled members as the structure upon which one reaches the next, higher level members.

Compression allows for easy dis-assembly and reassembly, an advantage compared to combinatorial approaches such as steel embedded concrete.

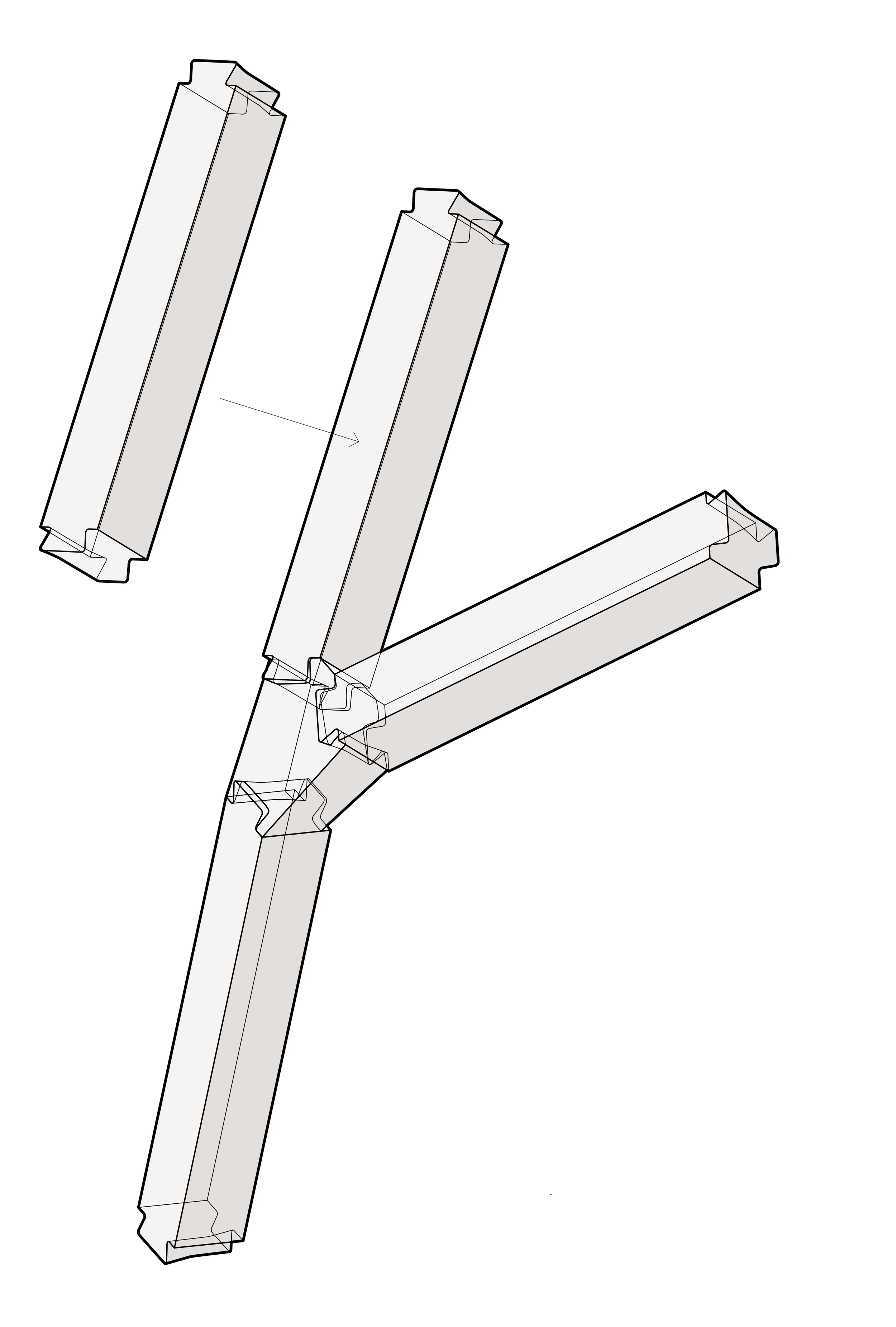

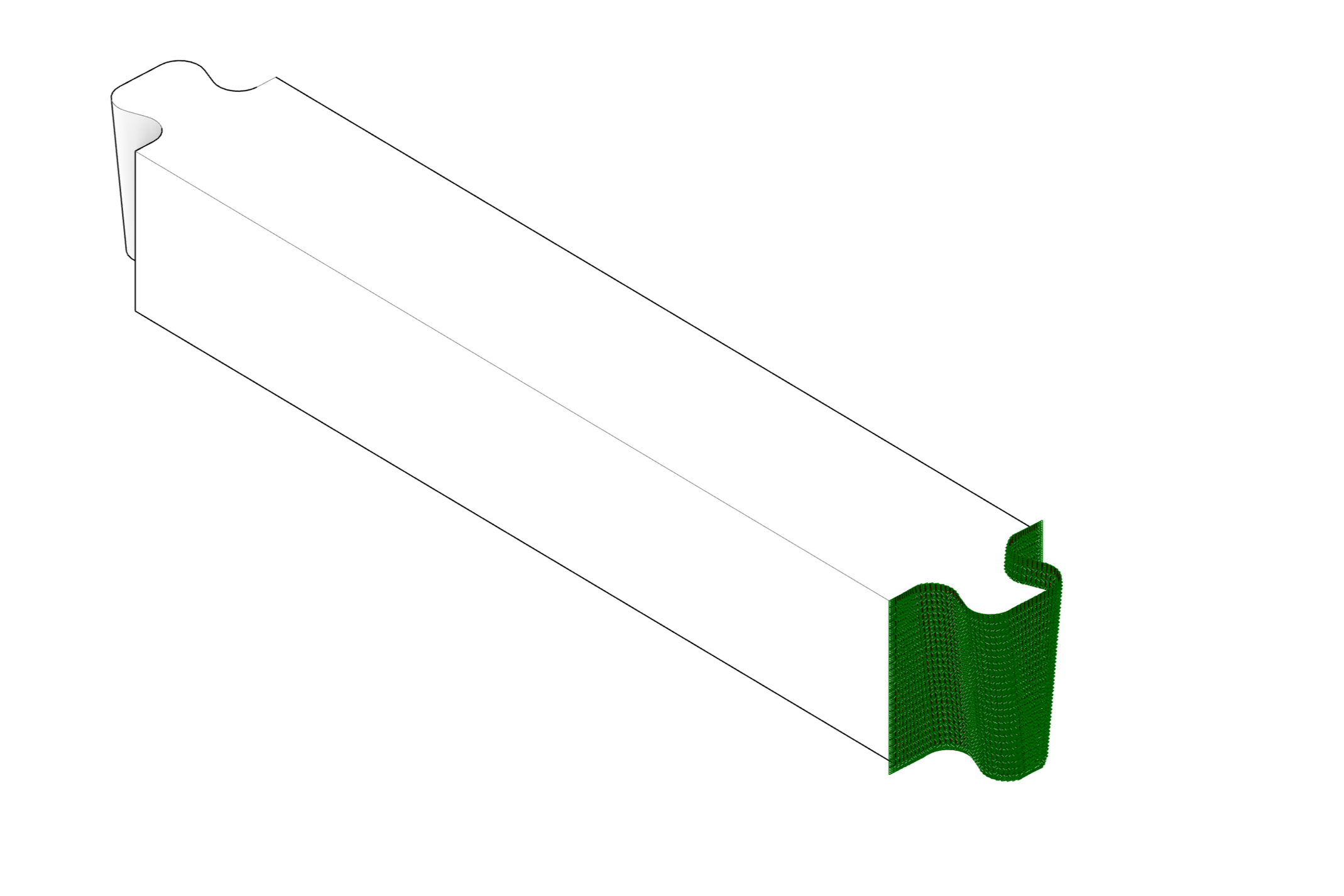

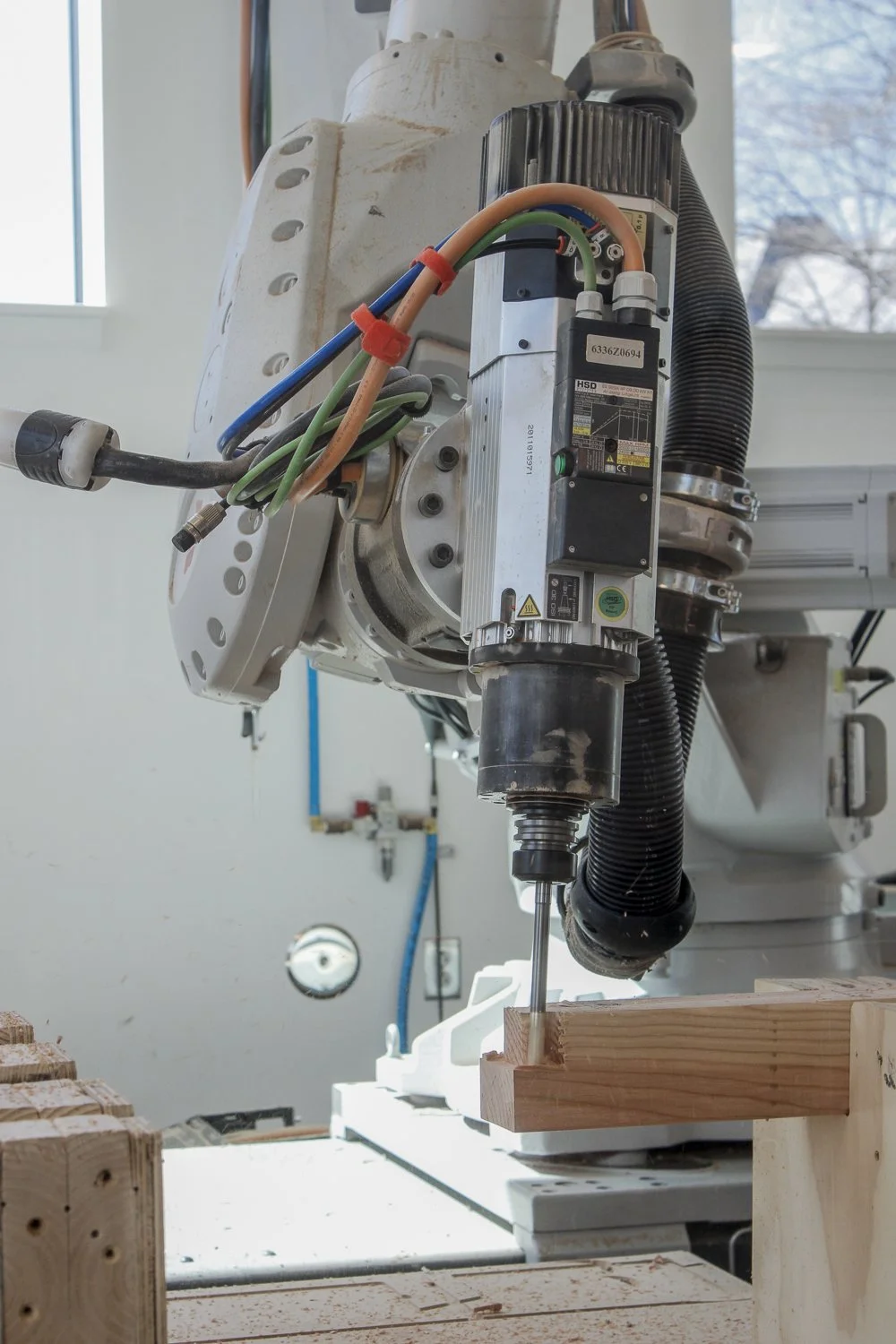

Joints and linear members, composed of CLT and glue laminated timber respectively, are designed to be robotically milled off-site, then assembled with mallets.

No use of glues, or other joining agents are included, in order to capitalize on the advantages of a compression-based system.

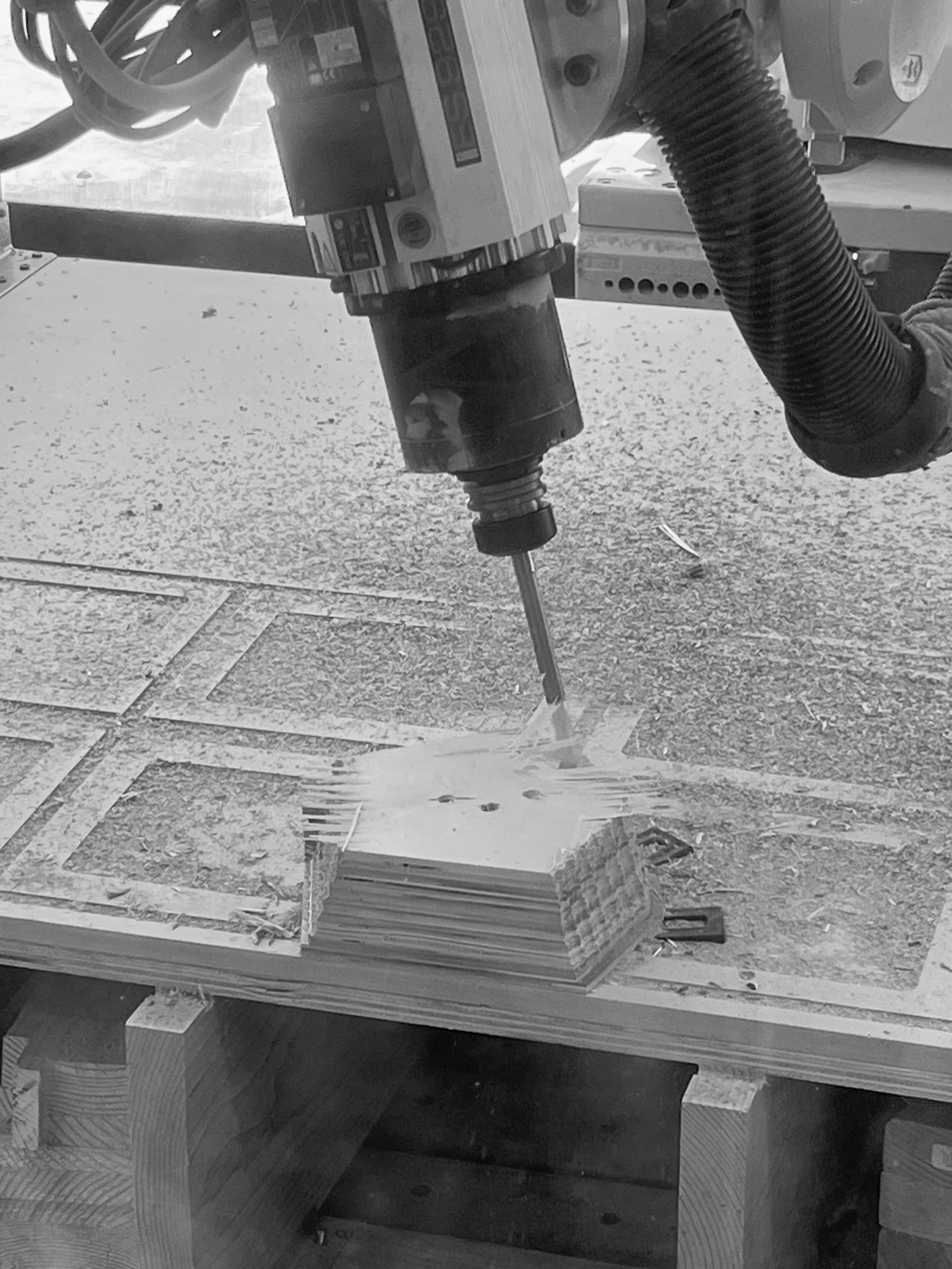

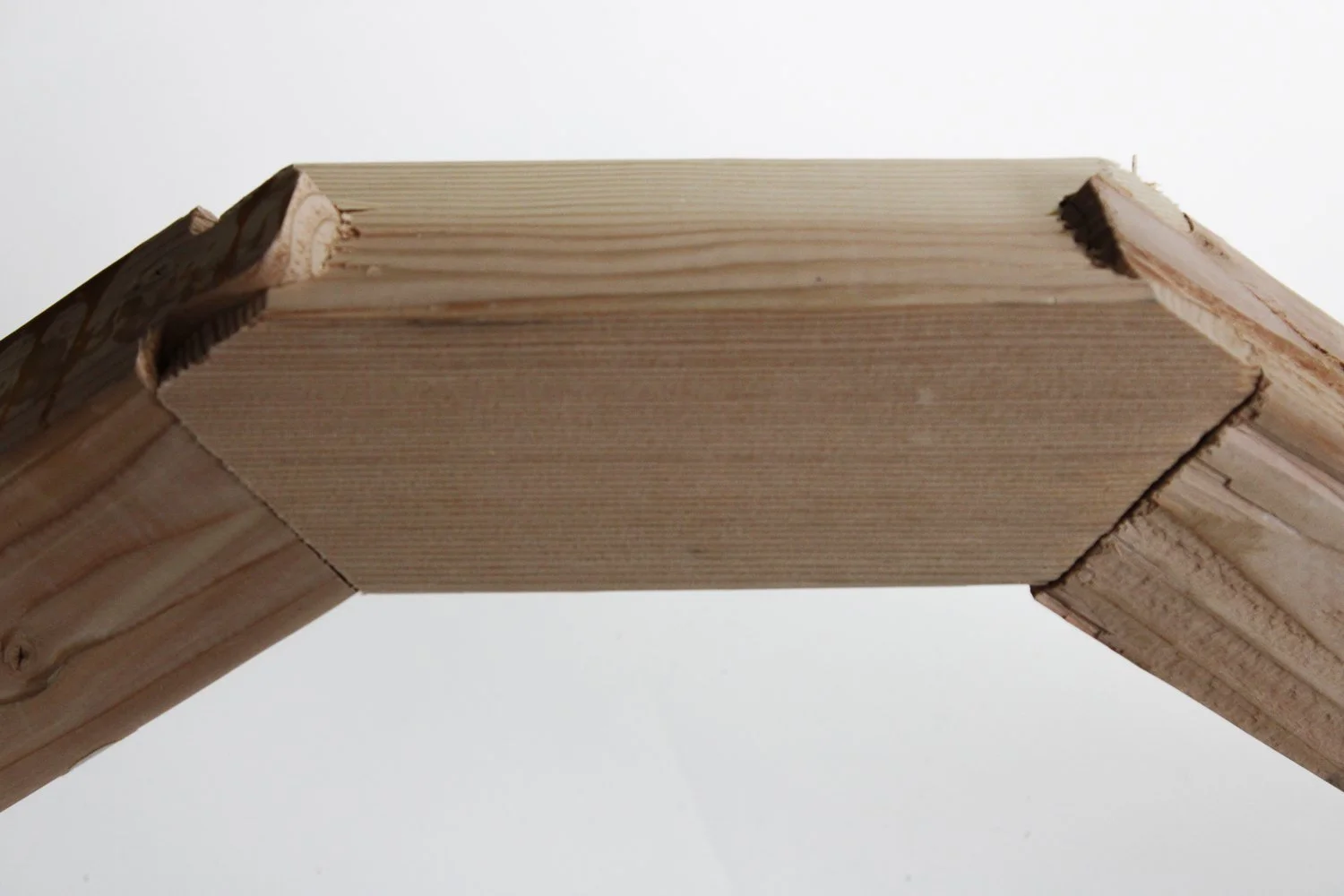

In order to test the capabilities of this wood to wood connection system, a full scale model was assembled using glued plywood nodes and 4x4” timber posts (3.5 x 3.5”).

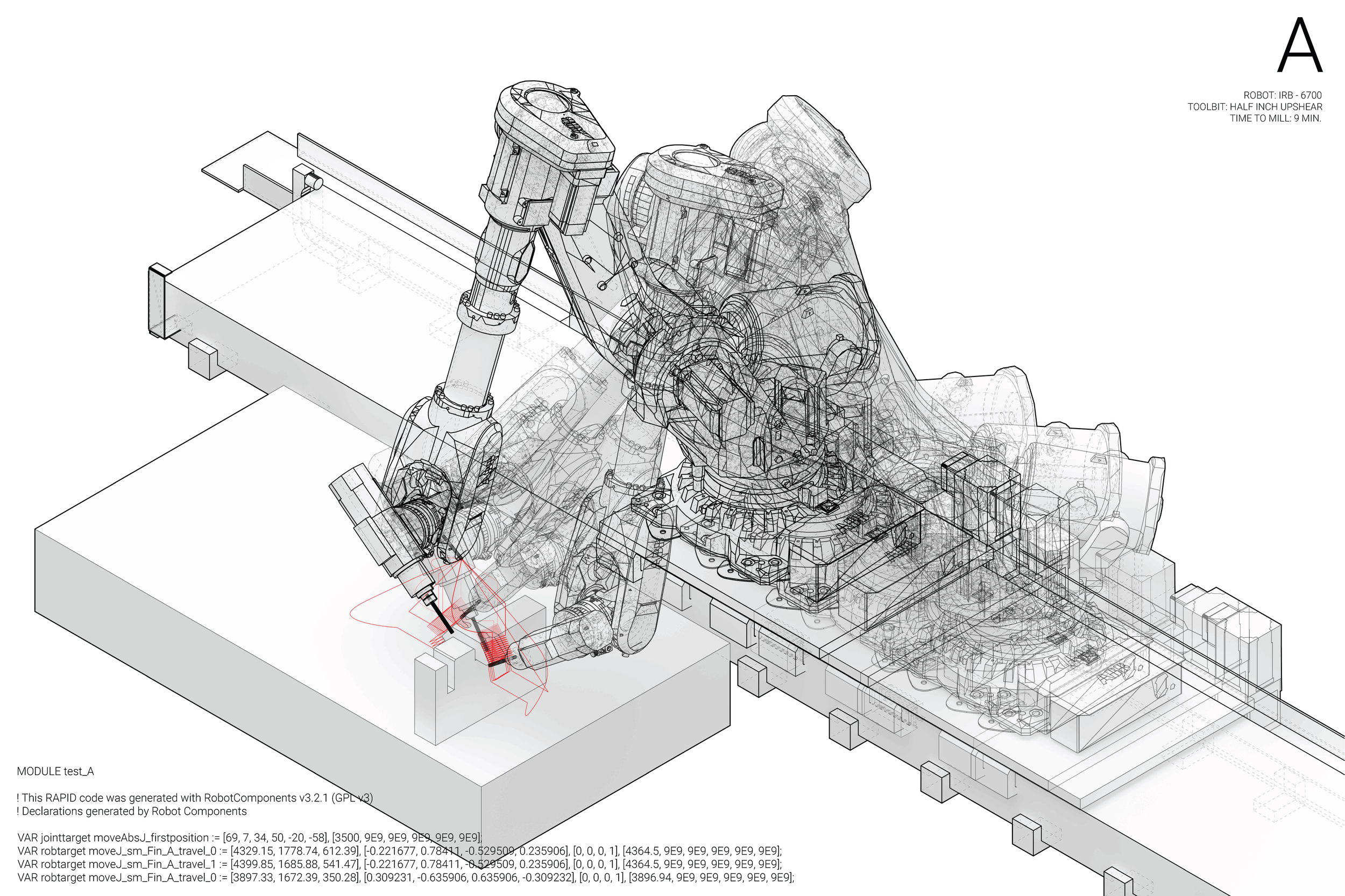

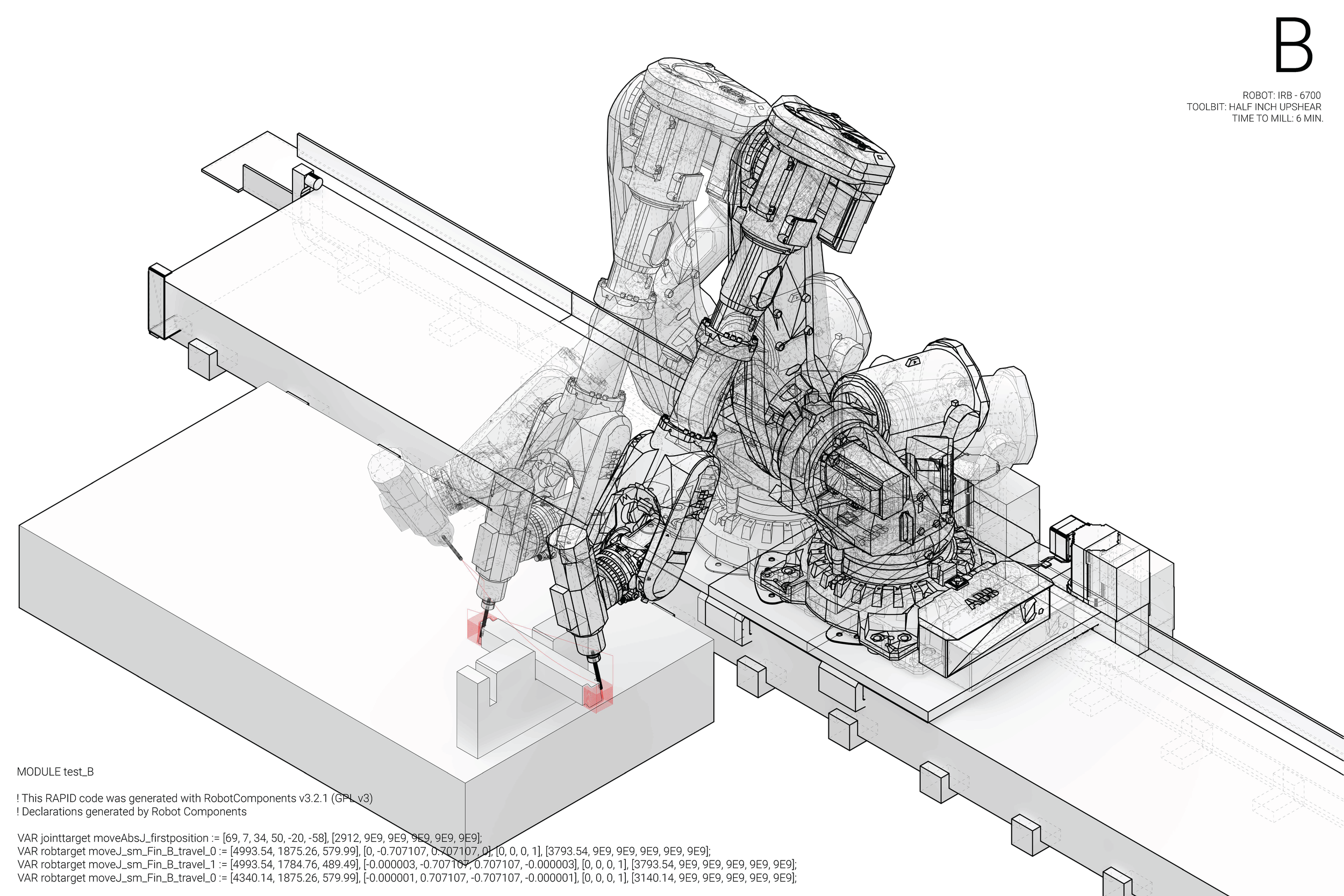

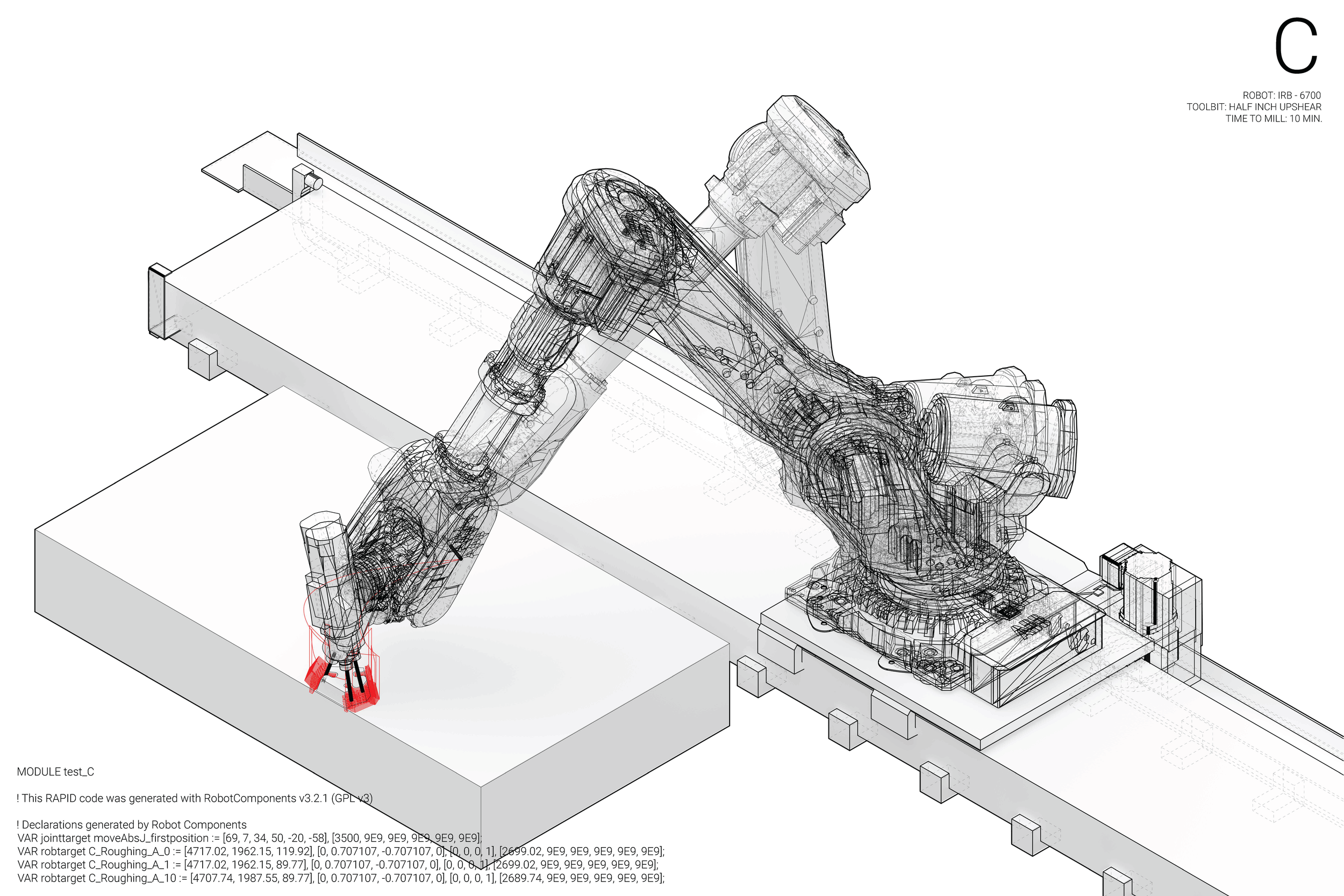

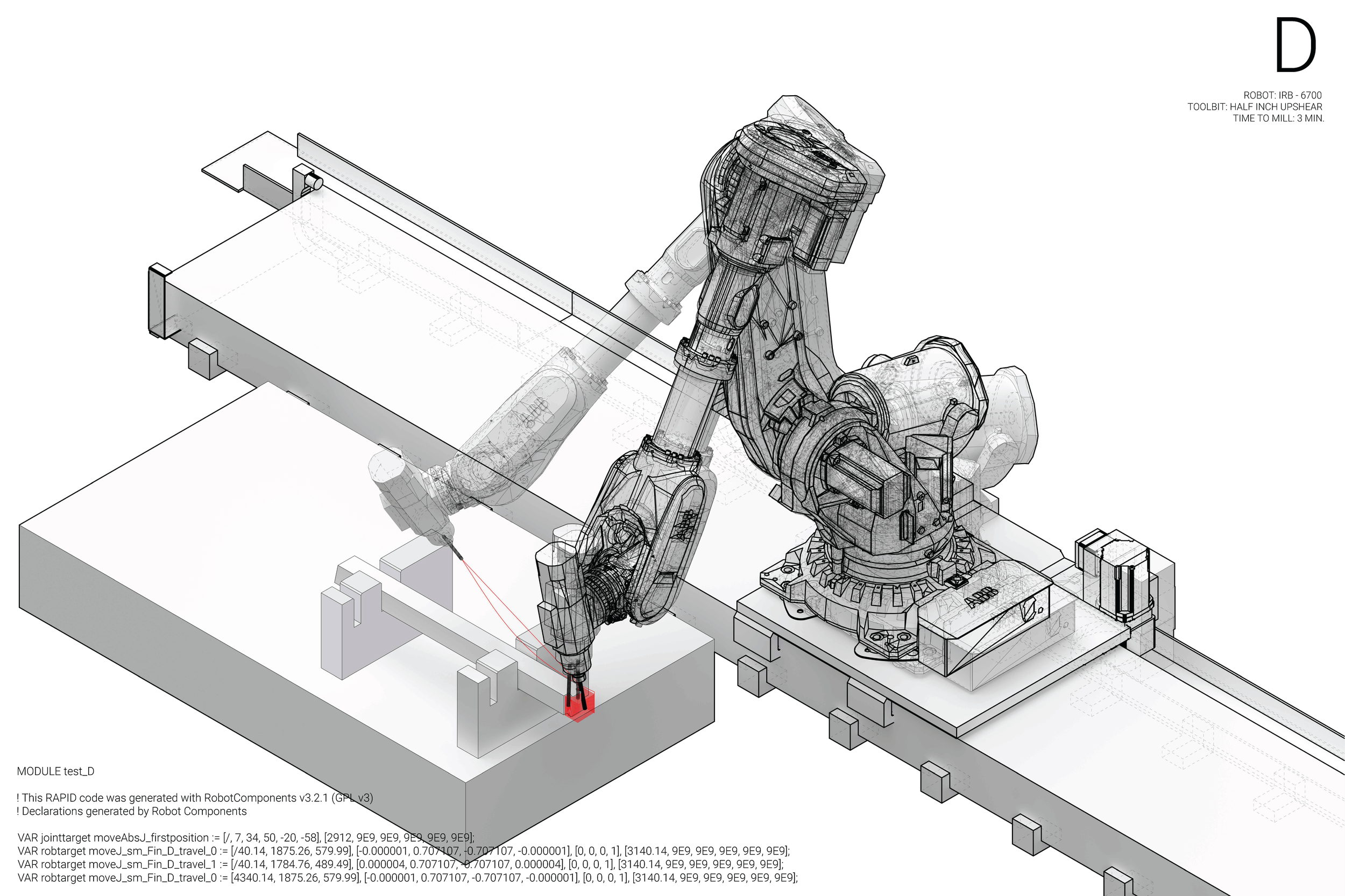

The assembly of node elements involved a process of stock gluing and shaping, followed by robotic milling with a 6-Axis IRB 6700 robot. The pieces were glued from 3/4” plywood, which were shaped into hexagonal stocks for the robot to mill.

Robotic milling involved the creation of a parametric script, from which the desired output surface could accurately and repeatedly be milled.

This required a grasshopper script that would create ruled, unsplit surfaces, slice those surfaces into layers which were each the depth of the tool bit radius, and offset those sliced layers by the radius.

Test iterations both in grasshopper and with the 6-axis mill experimented on the dimensions of the dovetail, the overhangs created, and the ability to precisely mill the angular geometry without unexpected collisions of the mill bit into the stock.

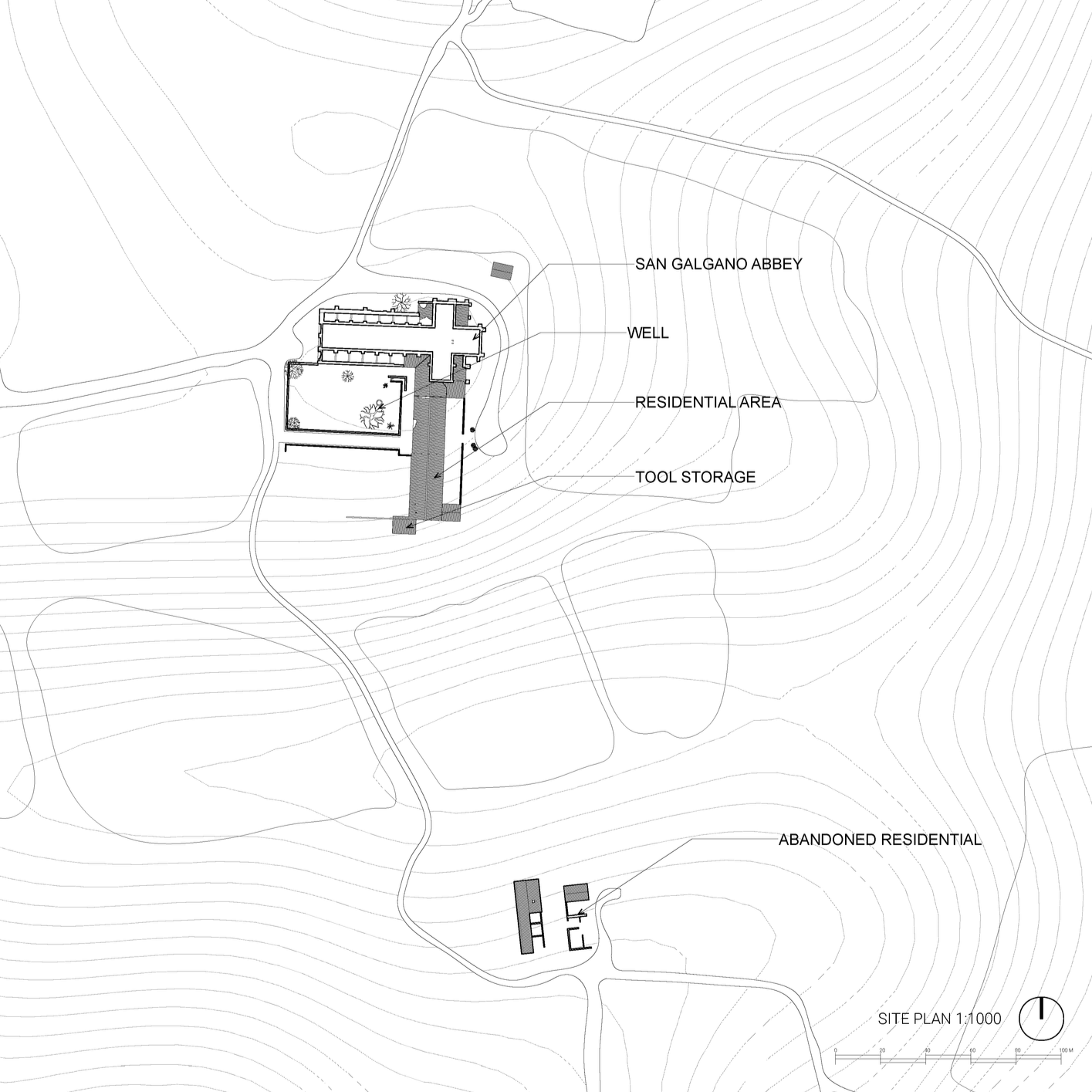

San Galgano

Constructed in the 13th century and located in Tuscany, San Galgano is a monastery which had lost its roof in 1786 after a collapse of its bell tower. Today only the walls remain in their 13th century style.

In order to begin iterating on a new roof for San Galgano, it was first modeled from sourced 3d scans and drawings. From there, our funicular strategy was used to design a series of vaulted structures, varying in pattern and size.

1’ Square glue laminated timber was determined by the FEA analysis. In addition, our system had to adapt and stretch in order to meet the challenges of real world construction.

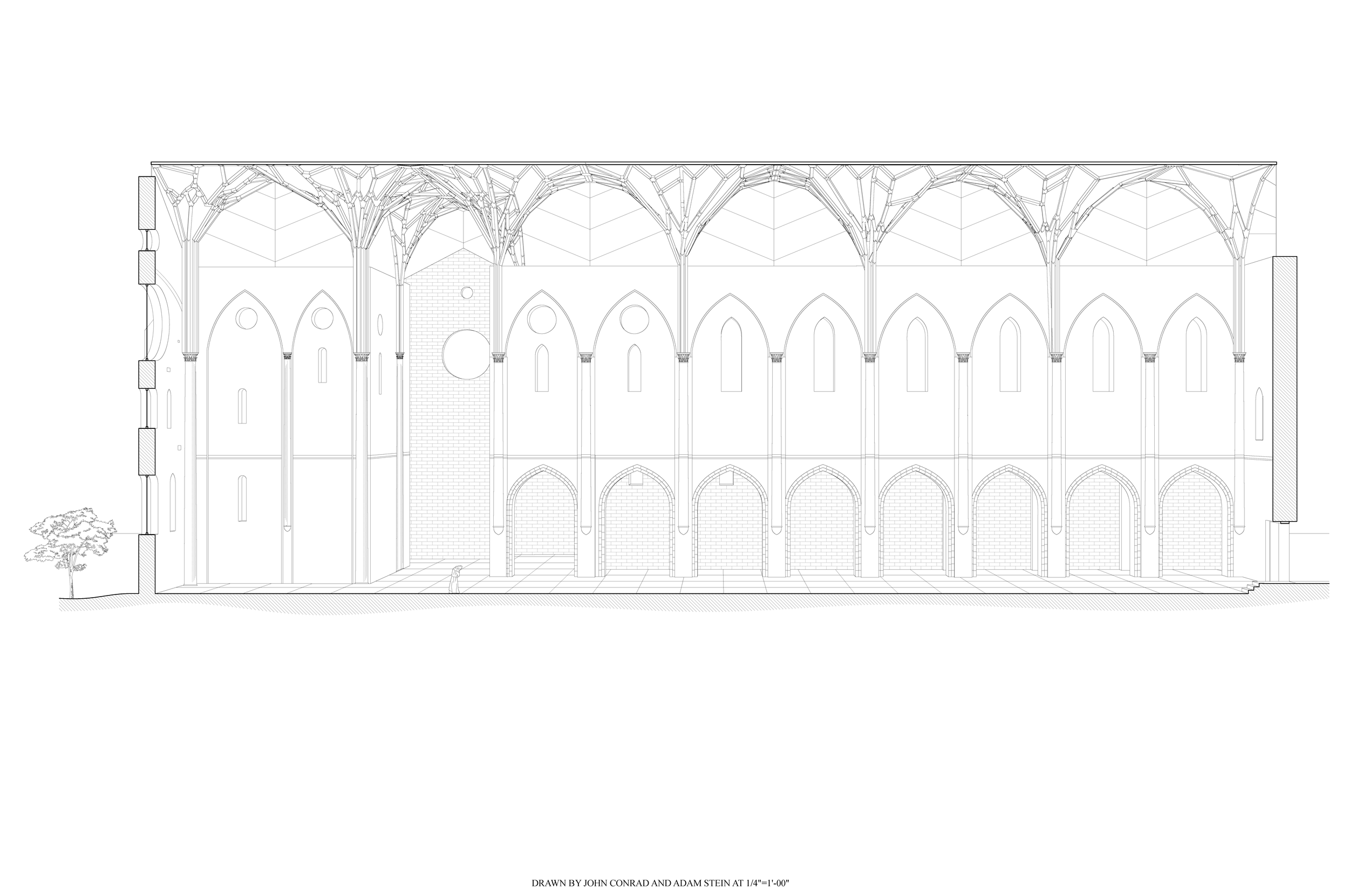

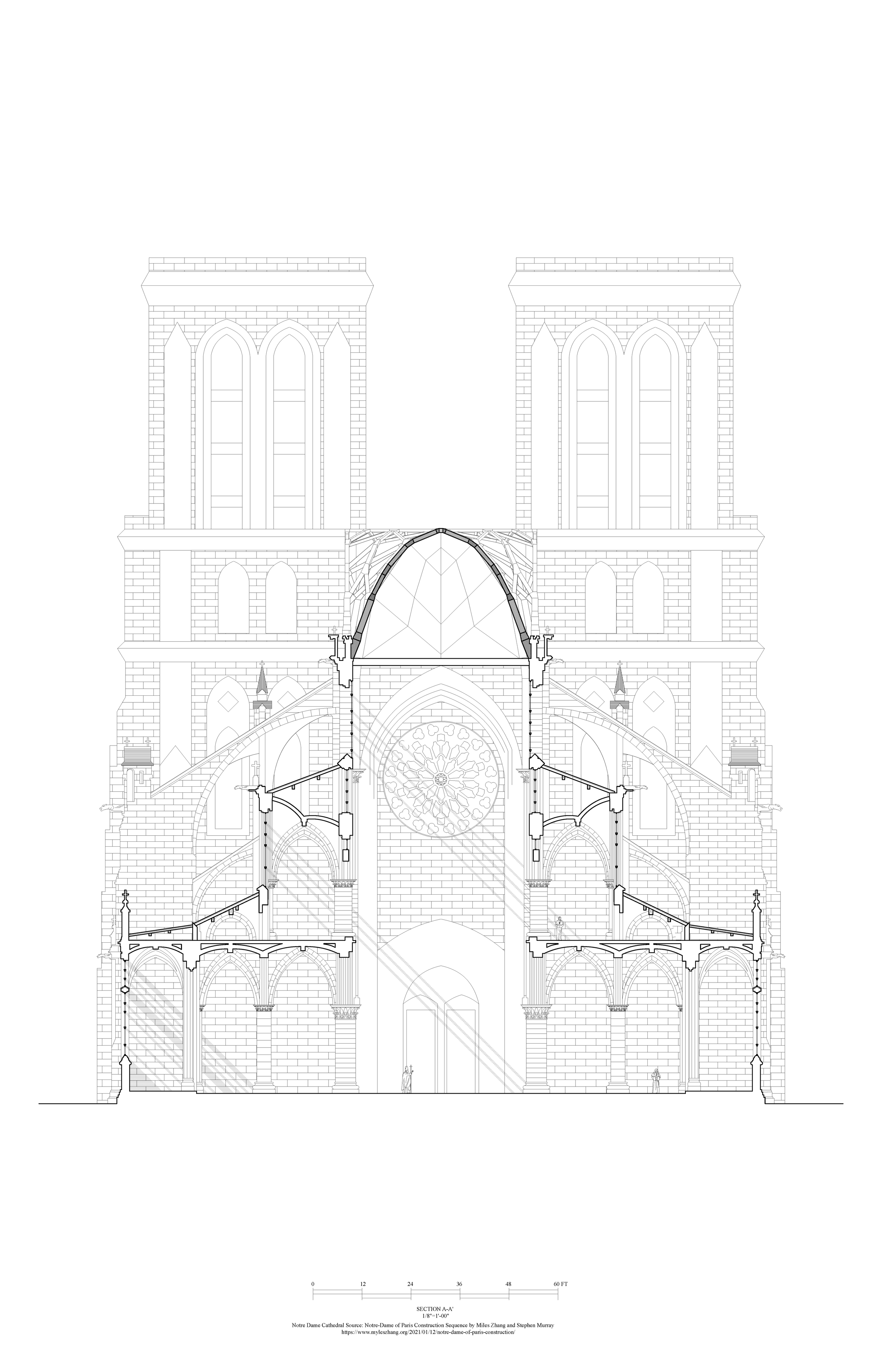

Notre Dame

Notre Dame, originally constructed from 1163-1345, was the victim of a fire in 2019 which destroyed most of the wooden roof, as well as its wooden spire. Notre Dame's roof was eventually reconstructed, re-opening on December 8th, 2024. The restoration took a total of 2,000 craftspeople and 500 tons of oak.

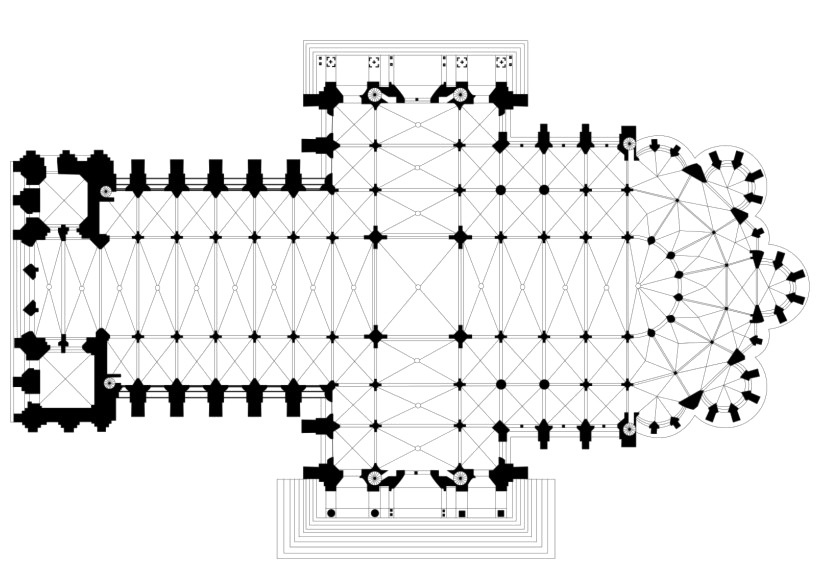

In order to accurately re-roof Notre Dame, 3d mesh data was obtained from the previous research done by Professors Myles Zhang and Stephen Murray on the construction sequence and documentation of Notre Dame.

As an alternative re-construction of Notre Dame's roof, this new process involves the use of Finite Element Analysis (FEA) in Karamba in order to add a variational beam sizing to the overall structure.

In collaboration with Annie Wang and Adam Stein, these 3d meshes were traced into two dimensional drawings to create the representations shown.

Date

Spring 2025

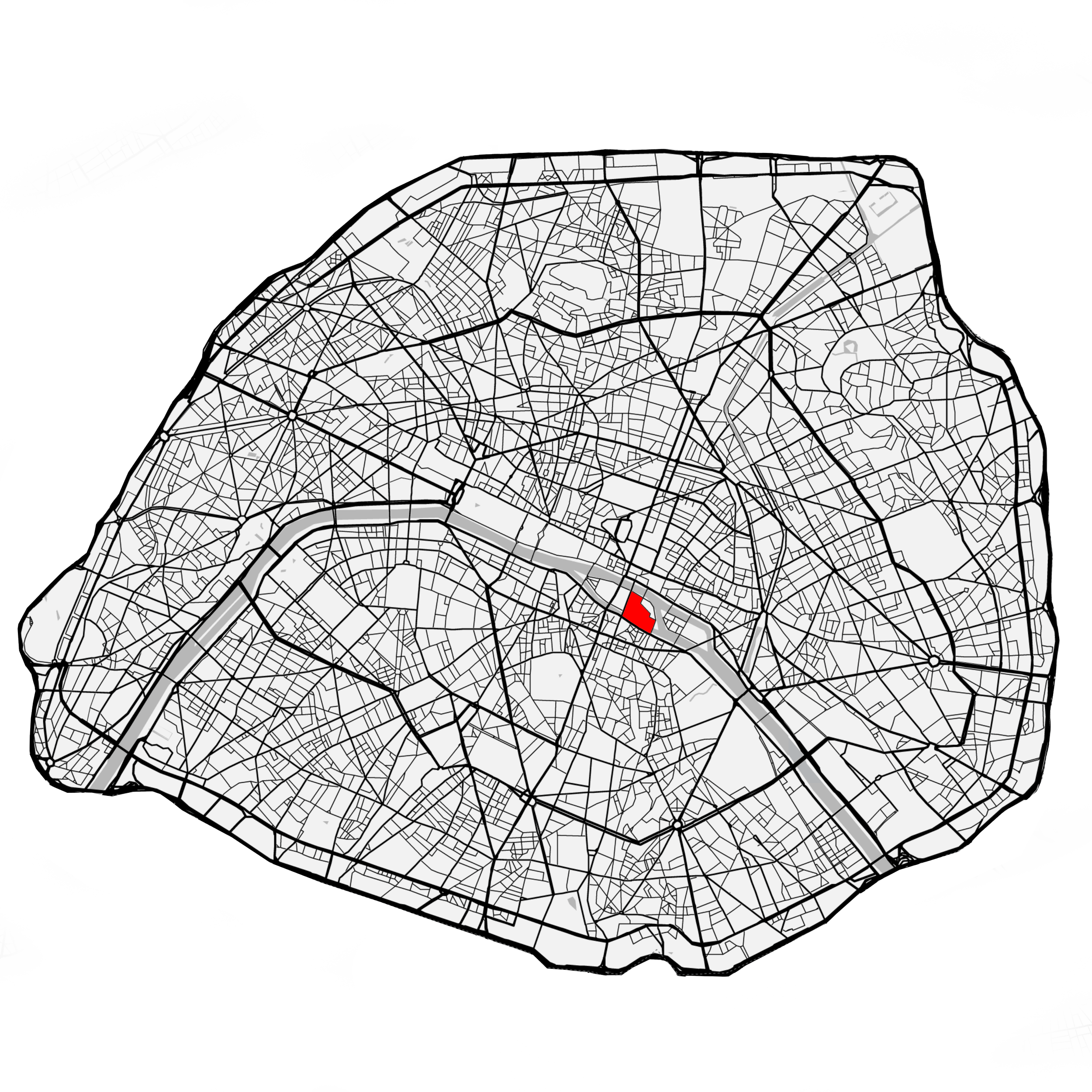

Location

Paris, France

Type

Structural Engineering, Robotic Fabrication

Phase

Research

Team

John Conrad, Prof.Martin Miller, Prof.Sasa Zivkovic, Adam Stein, Lawson Spencer, Annie Wang, Dr.Miles Zhang, Stephen Murray